Problems encountered in the construction of Xiang’an Tunnel

6 min readThe geological surveying is the premise and foundation of the study on the project construction scheme. The construction of cross-sea passages and in particular the construction of the undersea tunnel were closely related to the geological conditions The geological risk is the biggest risk source of undersea tunnels, so the entire undersea stratum structure must be ascertained through the whole construction process. The undersea geological surveying is more difficult than that on land, and the accuracy of the undersea surveying will be lower. There were few examples of undersea tunnel projects so China lacked the seabed surveying experience for the construction of undersea tunnel.

The geological surveys in seabed and on land are seemingly identical, but actually they are very different. Due to the seawater barrier, frequent tidal waters and large tidal range, the working environment for offshore surveying is more complex. The surveying process and the selection of the parameters for this process were completely different, so the seabed geological conditions could not be grasped accurately by adopting the conventional geological surveying methods used on land.

Based on the existing surveying technology for the construction of land tunnels, the constructors conducted a large number of comparative experiments and theoretical studies according to the characteristics of the undersea tunnel survey, optimized the parameters of thesurvey, and developed a set of advanced and effective surveying methods for the undersea tunnel project. The core technologies included the marine shallow seismic reflection surveying technology, the marine borehole and cross-hole seismic CT surveying technology, and the marine borehole water-pumping(pressing) test. The constructors gave their blood, sweat and tears in order to ascertain these processes and parameters, which were all forged through wisdom and sweat.

Acommon scene during the process was the surveyors on a ship or the coastal area, not for leisure, but for the surveying data, such as the data of ordinary water level, tidal level, surface width, depth, flow, flow rate, water quality, sand content, bleed-and-feed relationship between underground water and surface water, and the law of seasonal variation between them. They ascertained the distribution law of aquifer and aquitard, and the thickness, lithological character, and structural characteristics of the section within which the tunnel would be constructed. The pressure, direction of the surface water, the types, recharge, runoff and discharge conditions of groundwater were also ascertained.

In the early stage of the survey, the total length of the profile of offshore and onshore seismic surveying reached 166 kilometers.105 offshore boreholes,67 onshore boreholes,14 PS loggings,20 water pumping tests,20 water pressing tests, and a large number of on-site and laboratory test work were completed. The undersea topographic surveying of 18.55 km2 and a geological plane map of 25 km² were also done.

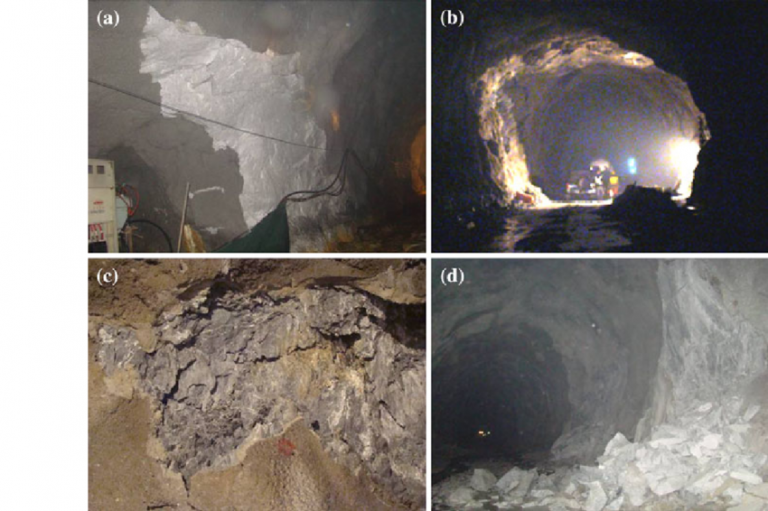

The surveying work was extremely tedious, but it would let the constructors know intuitively what problems they would encounter. For example, the soil samples including the rock(soil) core taken from the borehole can show the geological conditions. They were put into containers and had pictures taken immediately after coring, and then sent to the expert meeting for study.

In the eyes of experts, the hard rock, mud, or even the rock(soil) core of the yellow muddy water would reveal a lot of information. Zeng Chao said,”This information can help us to determine the distribution of the weak surrounding rock and the fault fracture zone, the boundaries of fully, strongly, moderately, and slightly weathered layers, the physical and mechanical properties of rock and earth mass, and the effect of the groundwater.”

The experts had discussions while watching the process, and their expressions were always changing,”This is fully weathered rock.. This is also difficult to handle, because it’s stronglyweathered rock.”The simple explanation was that, the fully weathered rock was an extremely soft rock. After being hammered, pits would appear on the rock. The rock core can be crumbed by hand.The strongly weathered rock is very crisp, fragmentary, and it can be excavated by a pickaxe. It is difficult to imagine constructing a tunnel in such rocks.

Of course, the surveying data with which the experts were most concerned were the undersea weathered slots, which were also the most difficult part of the Xiangan Tunnel construction. The weathered slot is a deep pit formed by the weathering of the undersea stratum. It just like a V-shaped tank embedded in the rock, with silt and sand filled up its lower half. It embeds in the rock vertically, connecting the seawater. If there was a minor mistake during the construction, the water pressure of dozens of meters seawater would rip a hole in the tunnel, and the whole tunnel could be scrapped.

From March to May 2003, in the geological surveying carried out during the preliminary design stage, several major weathered slots were found.”We drilled 13 boreholes outside the weathered slots in a spacing of 2 m, and conducted sampling, testing. The accumulated footage was 765.5 m,”Zeng Chao said,”Verified by the borehole test, the strongly weathered layer was very thick. The high-angle fractures and fracture characteristics were found in some rock cores, which indicated that the construction difficulty would be extremely high.”Later, these weathered slots were named as F1,F2,F3 weathered slots and an F4 weathered capsule.

The construction of the cross-sea section was very difficult. Similarly, the surveying results of the two ends of the Xiang’ an Tunnel were not optimistic: heavily weathered strata were found in the Wutong end, and permeable sand strata were found in the Liuwudian end in Xiangan.

In the designing scheme, Xiangan Tunnel’s main tunnel was a three-lane tunnel, with a clear width of 13.5 m and a clear height of 5.0 m in construction clearance. It had a maximum excavation span of 17 m,a maximum excavation height of over 12 m, and a maximum excavation area of 170 m². For such a huge tunnel, unless it is all constructed in the very complete and hard rock stratum, the construction could easily go wrong when they encounter weak geological conditions.Unfortunately, the geological conditions on both the Wutong end and the Liuwudian end were not very favorable.

Thus, before the formal excavation, the construction concepts came out: highlight the water control, conduct the dynamic construction, protect the surrounding rock, attach equal importance to quality and aesthetics, and protect the environment, which became the five construction concepts of the Xiangan Tunnel construction.

“This was critical. Being the first, we have to grasp the characteristics of it. We have to know ourselves as well as the enemy. We never fight without preparation.”Huang Lingqiang, General Manager of Xiamen Road & Bridge Construction Group at that time, said,”From the very beginning, any failure was unacceptable in the Xiangan Tunnel construction, because the risk was so huge.The endless seawater was just like a sword hanging over our heads.”

These five concepts were always followed throughout the entire scheme, processes and methods of the Xiangan Tunnel construction.

“Surveying before Tunneling”was the most intuitive interpretation of the principle of advancedgeological forecast in the Xiangan Tunnel construction. Its purpose was to “know fairly well the geological conditions beforehand, and carry out the construction scheme with a purpose”. The integrated application of the world’s advanced geological surveying technologies and equipment was conducted in the Xiangan Tunnel construction, including: the TSP seismic detection with a range of 100 m to 150 m, the geological radar with a range of 10 m to 30 m, the infrared water detection, the whole course undersea horizontal borehole for direct coring, the geological sketch of the tunnel face, etc. These comprehensive advanced geological forecast technologies functioned like the”X-ray Eyes”, to provide a clear view of the geological conditions over one hundred meters ahead.

Zeng Chao, Vice President and Chief Engineer of Xiamen Road & Bridge Construction Group, said,”The geological forecast was like a CT examination in a hospital, using multiple methods such as geophysical survey, drilling, testing, water pumping (pressing) test. Among them, the geophysical surveying adopts seismic reflection methods to conduct longitudinal (northeast direction) and latitudinal(southeast direction) meshwork geophysical surveys. The coring and sampling works were conducted in several horizontal boreholes drilled from the tunnel face to the section that would be excavated. The longest one was about 70 meters. Meanwhile, various tests were conducted on the rock mass in order to understand the water conditions and geological conditions in the stratum.

It is worth mentioning that, in the design of Xiangan Tunnel,a service channel of a smaller diameter was designed between the two driving tunnels. On the one hand, it could be used as a municipal public pipe gallery or an emergency passageway. On the other hand, through the light section advanced excavation, it acted as the “geological pilot hole”and the “test hole”, which provided important references for the subsequent large section main tunnel construction.